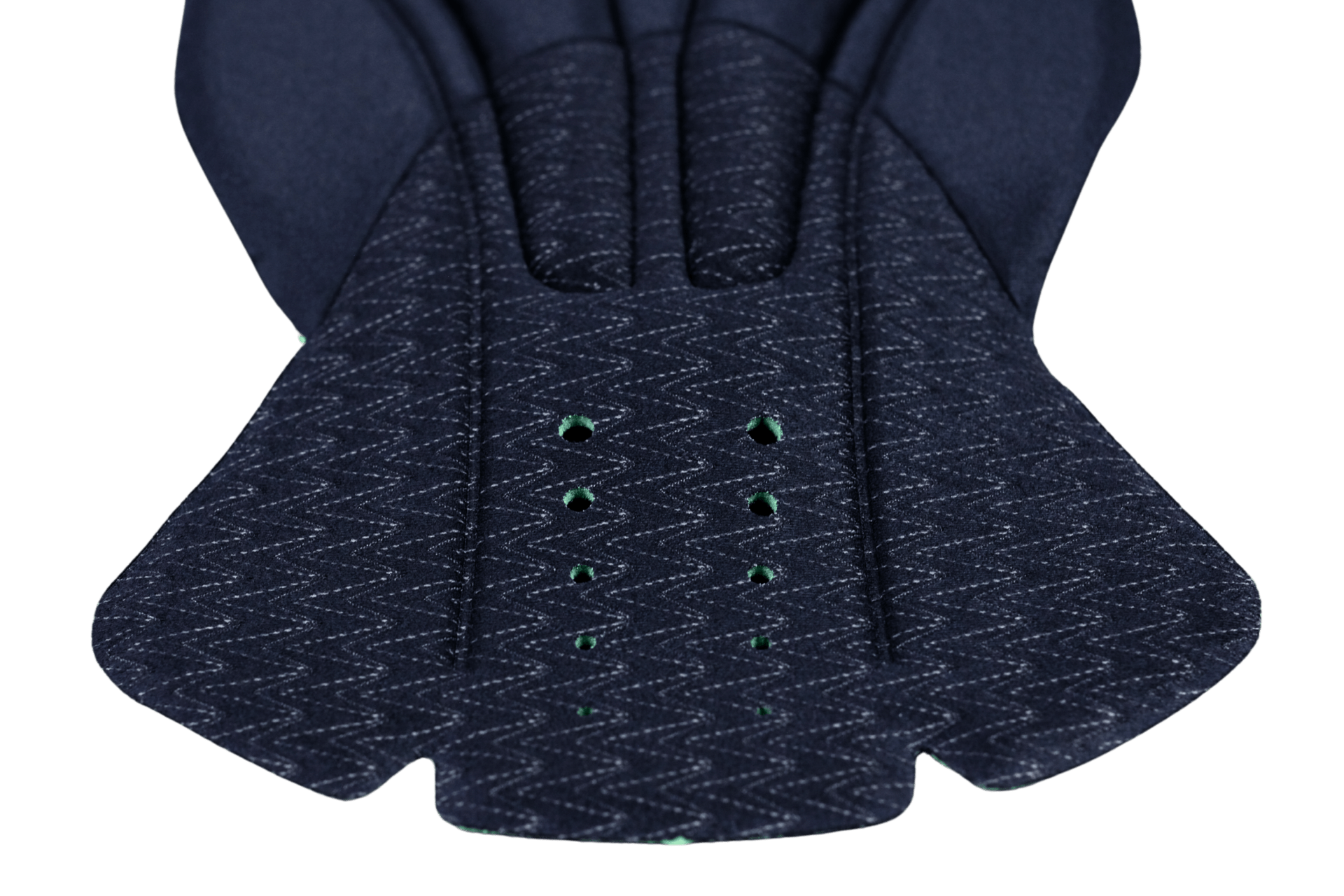

Wkładka N3X Elastic Interface, produkowana dla marki Inoni, to innowacyjny produkt, który wykorzystuje zaawansowaną technologię druku 3D w celu zapewnienia maksymalnego komfortu i wydajności podczas jazdy na rowerze. Poniżej przedstawiam szczegóły dotyczące jej charakterystyki i zalet:

Technologia N3X

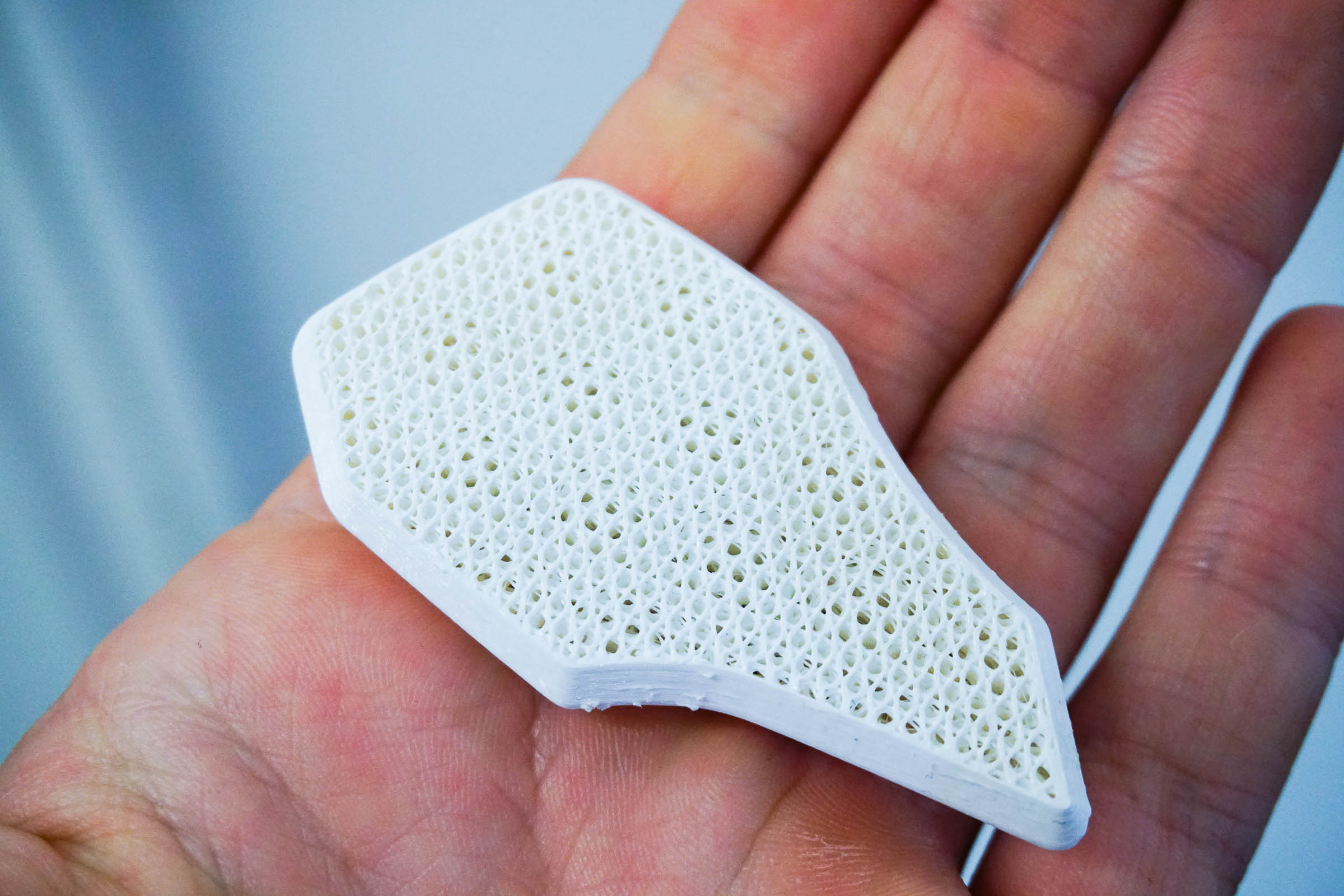

Druk 3D: Wkładka N3X jest pierwszą na świecie wkładką rowerową wykonaną w technologii druku 3D. Dzięki temu możliwe jest precyzyjne kontrolowanie struktury materiału, co pozwala na dostosowanie gęstości i wsparcia do różnych obszarów ciała rowerzysty.

- Hydrofobowość: Materiał wkładki jest hydrofobowy, co oznacza, że nie chłonie potu i szybko schnie. To zwiększa komfort użytkowania, szczególnie podczas długich tras.

- Oddychalność: Otwarta struktura wkładki zapewnia lepszą cyrkulację powietrza, co pomaga w regulacji temperatury skóry i zmniejsza ryzyko przegrzania.

- Ergonomia: Dzięki zastosowaniu druku 3D wkładka oferuje zróżnicowane strefy wsparcia, które są dostosowane do anatomii rowerzysty i pozycji podczas jazdy.

Zalety wkładki N3X

- Komfort i wydajność: Wkładka zapewnia pełną swobodę ruchów, stabilność w siodle oraz trwałą ochronę nawet podczas intensywnej jazdy.

- Ekologiczna produkcja: Proces produkcji wkładek N3X jest całkowicie bezodpadowy. Drukowane są tylko te elementy, które są potrzebne, co minimalizuje wpływ na środowisko.

- Personalizacja: Możliwość dostosowania wkładki do indywidualnych potrzeb użytkownika dzięki precyzyjnemu sterowaniu parametrami technicznymi materiału.

Współpraca z Inoni

Marka Inoni wykorzystuje tę technologię w swojej kolekcji produktów kolarskich, takich jak spodenki z wkładką N3X. Produkty te charakteryzują się wyjątkowym komfortem i nowoczesnym designem, idealnym dla miłośników kolarstwa szosowego i długich tras.

Wkładka N3X Elastic Interface to przykład innowacji w branży odzieży sportowej, która łączy zaawansowaną technologię z funkcjonalnością i troską o środowisko.